Product Category

New products

-

Rackmount Liquid-Liquid CDUs

The secondary side heat exchange unit CDU is mainly used for heat ...

-

Coolant Distribution Unit

The Coolant Distribution Unit (CDU) is the central component of the ...

-

-

-

-

Water Chillers Supplier from China

Features 1. Compressor: adopt international brand semi-closed ...

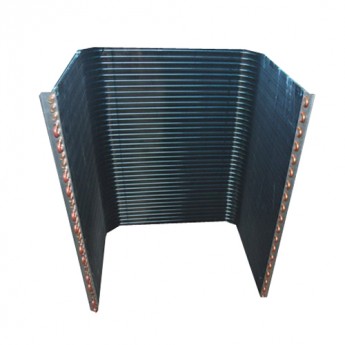

Heating And Cooling Coil

1. Heating and cooling coil can be used in air conditioner, cold room, freezer, refrigerator and other area.

2. Fin: flat or corrugated aluminum foils; hydrophilic or bare fin.

3. Tube: copper pipe

4. Φ7mm, φ7.94mm, φ9.52mm ,φ12.75mm, φ15.88 of tube O.D. available

5. Customized service is available according to customer's drawings to meet end user's specified requirements.

6. Materials of fin and tube per customer's need, it could be aluminum, copper or stainless steel

7. Leak test: 2.5Mpa water test

8. Producing process: tube bend, press fins, expand tube, welding, leak test, dry, inspect, pack.

Product Description

|

Item |

Heat exchanger Type |

Operation medium |

Operation pressure (MPa) |

Application |

|

1 |

Φ16/Φ9.52/Φ12.7 Copper tube with aluminium fin |

Cold/hot water |

≤1.6 |

Used for combined air handling unit, fan coil etc air conditioning devices |

|

2 |

Φ18/Φ20 Steel pipe winding with steel sheet |

Steam |

≤0.2 |

Used for combined air handling unit, fan coil etc air conditioning devices |

|

3 |

Φ16/Φ9.52/Φ12.7 Copper tube with aluminium fin |

Brine |

≤1.6 |

Used for heat transfer in cold storage and all kinds of low temperature systems |

|

4 |

Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin |

Ethylene glycol |

≤1.6 |

Used of energy recovery and low temperature system devices |

|

5 |

Φ16 Copper tube with aluminium fin |

Ice mud |

≤1.6 |

Used for dry operation condition, fresh air dehumidification etc systems |

|

6 |

Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin |

R22 |

≤1.9 |

Used for industry and commerce air conditioning system |

|

7 |

Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin |

R407C |

≤1.9 |

Used for industry and commerce air conditioning system |

|

8 |

Φ9.52/Φ7.94/Φ7 Copper tube with aluminium fin |

R134a |

≤3.1 |

Used for vehicle and vessel etc transportation devices |

Fin mold for copper tube heat exchanger

|

Fin Pattern |

Copper Tube O.D.(mm) |

Row Space(mm) |

Hole Space(mm) |

Common copper tube thickness(mm) |

Fin Space(mm) |

|

A |

7 |

12.7 |

21 |

0.28~0.3 |

1.3 |

|

B |

7.94 |

15.88 |

25.4 |

0.3~0.35 |

1.8~3.0 |

|

C |

7.94 |

19.05 |

22 |

0.3~0.35 |

1.4~3.0 |

|

D |

9.52 |

22 |

25.4 |

0.3~0.35 |

1.6~3.2 |

|

E |

9.52 |

22 |

25.4 |

0.3~0.35 |

3.5~6.35 |

|

F |

9.52 |

15.88 |

25.4 |

0.3~0.35 |

1.6-2.6 |

|

G |

9.52 |

12.7 |

25.4 |

0.3~0.35 |

1.6-2.5 |

|

H |

9.52 |

21.65 |

25 |

0.3~0.35 |

1.6~3.2 |

|

I |

9.52 |

21.65 |

25 |

0.3~0.35 |

3.2~6.35 |

|

J |

12.75 |

27.5 |

31.75 |

0.4-0.5 |

1.5~3.5 |

|

K |

15.88 |

33 |

38.1 |

0.4-0.6 |

1.5~4.0 |

|

L |

15.88 |

34.64 |

40 |

0.4-0.6 |

2.6~3.5

|

Fin mold for aluminum tube heat exchanger

|

Fin Pattern |

Al Tube O.D.(mm) |

Row Space(mm) |

Hole Space(mm) |

Common Al tube thickness(mm) |

Fin Space(mm) |

|

A |

7 |

12.7 |

21 |

0.5~0.71 |

1.3~2.5 |

|

B |

7.94 |

17.05 |

20.05 |

0.5~0.71 |

1.8~3.0 |

|

C |

7.94 |

15.88 |

25.4 |

0.5~0.71 |

1.8~3.0 |

|

D |

9.52 |

15.88 |

25.4 |

0.5~0.71 |

1.6-2.6 |

|

E |

9.52 |

12.7 |

25.4 |

0.5~0.71 |

1.6-2.5 |

|

F |

9.52 |

21.65 |

25 |

0.5~0.71 |

1.6~5 |

|

G |

12.75 |

27.5 |

31.75 |

0.7-1.2 |

2.5~5 |

|

H |

15.88 |

33 |

38.1 |

0.7-1.2 |

2.5~5 |