Product Category

New products

-

Rackmount Liquid-Liquid CDUs

The secondary side heat exchange unit CDU is mainly used for heat ...

-

Coolant Distribution Unit

The Coolant Distribution Unit (CDU) is the central component of the ...

-

-

-

-

Water Chillers Supplier from China

Features 1. Compressor: adopt international brand semi-closed ...

Product Description

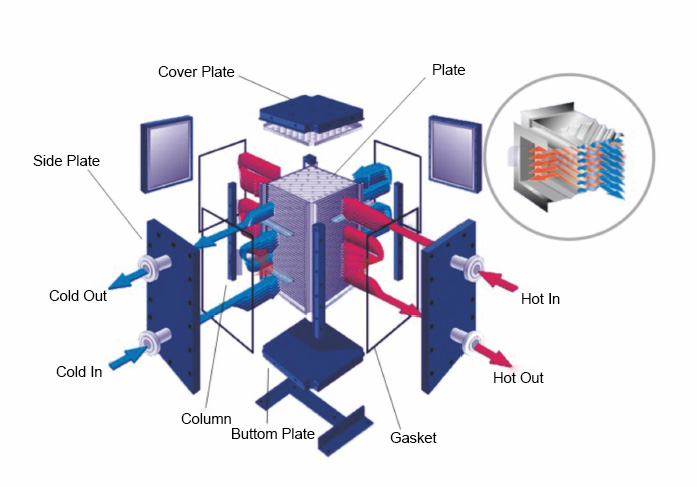

The laser frame plate heat exchanger combines the advantages of plate heat exchangers and shell and tube heat exchangers, maintaining the advantages of traditional plate heat exchangers such as high heat transfer efficiency, compact structure, high temperature resistance, good sealing performance, safety and reliability, and can also be used under higher pressure and temperature conditions. Suitable for steam condensation and liquid liquid heat exchange, especially suitable for the heat exchange needs of special media in industries such as power, petrochemical, coking, pharmaceutical, metallurgical, refrigeration, pulp and paper industry, etc.

The reasonable setting of the process ensures the reasonable matching of the heat transfer efficiency and Friction loss of the equipment. The shell adopts a Hexahedron detachable structure, which can also meet the process requirements of mechanical cleaning and chemical cleaning inside the equipment.

Models

Parameter Table of Laser

Semi Welded Plate Heat Exchanger

Model

Overall Dimension(mm)

Maximum Assembly area

Maximum Nozzle Diameter

Maximum Nozzle Diameter

Standard Pressure Range

Max Length

Width

Height

HU-06D

960

262

910

9

DN150

DN80

≤3.0MPa

HU-18D

1050

367

1425

35

DN200

DN80

HU-30D

2750

427

1664

90

DN250

DN125

HU-40D

2800

450

1974

120

DN250

DN100

HU-60D

2900

511

2186

180

DN350

DN200

HU-90D

3100

718

2560

450

DN500

DN300

HU-110D

3300

718

2860

550

DN500

DN300

≤2.8MPa

HU-130D

3500

718

3160

650

DN500

DN300

Standard temperature range:-20℃ to 250℃

(m2)

of the Hot side

of the Cold Side

Application

●Oil refining and mining industry.

● Petrochemical

● Oil & Gas

● Energy Power

● Metallurgy

●Biomedical